Things to consider when choosing an infrared thermometer

Things to consider when choosing an infrared thermometer |

Infrared thermometers are popular temperature measuring devices as they are easy to use, take non-contact measurements (so there’s no risk of contamination), are quick to take a measurement and they can measure temperatures from a distance. This makes them popular for food and warehousing applications, as well as manufacturing, electrical and mechanical applications. There are a number of factors that must be considered when choosing an infrared thermometer and these are listed below. | |

Target temperature | |

| You have purchased a weather station through us that allows you to measure temperature, humidity, rainfall, wind speed and barometric pressure. You are most interested in rainfall data as you use the station to gauge how much rain has fallen in your garden; however you are unsure as to where to mount the station in order to obtain the most accurate results. IC7218 is suitable for temperatures up to 110C, whereas the IC7226 is suitable for temperatures up to 1000C. | |

Target material | |

| Products like wood, plastic, glass and paint tend to work well with infrared thermometers as they have high emissivity values (around 0.90 to 0.95). Emissivity is a measure of the ability of a material to emit energy as thermal radiation and ranges on a scale from 0 to 1. A lot of infrared thermometers are set as default to an emissivity of 0.95 and some are fixed at this value, but some will allow you to adjust this value. Ultimately the emissivity setting on the thermometer should match the emissivity value of the material you are measuring. Metals, particularly unoxidised metals, tend to have low emissivity values, which can make measurements tricky and you may be better of considering a contact thermometer for these applications. | |

Target size and the distance to the target | |

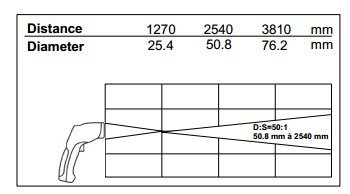

The size of the target and the distance you wish to measure from are very important things to

consider when choosing an infrared thermometer. You will often see a distance to spot ratio (D:S)

listed on a product. This is a ratio of the distance to the object and the diameter of the

measurement area. For example, if the thermometer has a D:S ratio of 10:1 then measurement of an

object 1m away will average the temperature over a 10cm diameter area. Larger spot ratios such as

30:1 (in the

IC7226

) or 50:1 (in the

KIRAY300

) mean that you can measure smaller areas from further away.

The size of the target and the distance you wish to measure from are very important things to

consider when choosing an infrared thermometer. You will often see a distance to spot ratio (D:S)

listed on a product. This is a ratio of the distance to the object and the diameter of the

measurement area. For example, if the thermometer has a D:S ratio of 10:1 then measurement of an

object 1m away will average the temperature over a 10cm diameter area. Larger spot ratios such as

30:1 (in the

IC7226

) or 50:1 (in the

KIRAY300

) mean that you can measure smaller areas from further away.

| |

Recommended Products | |

| IC7218 – Mini Non-Contact IR IP67 Thermometer | |

| |

| High Temperature Non-Contact Thermometer - IC7226 | |

| |

| KIRAY300 - Kimo Infra Red Thermometer (50 to 1 Ratio) with Dual Laser Beam (-50C to 1850C) and K thermocouple probe | |

| |