How to build a solar cooker at home, ditch the stove (if you can wait).

How to build a solar cooker at home, ditch the stove (if you can wait). |

How to build a solar cooker at home, ditch the stove (if you can wait).With the weather warming up for this week’s experiment we built a simple solar cooker to try and boil an egg just from the energy of the sun. Did it work, is the Australian sun hot enough to boil an egg? Check out the results below, we used the Testo 175 T3 to track the temperature, but the true results are in the taste test! Each week new products are added to the site, this months favourites are listed below:

Please remember if you have any questions regarding tests you need to conduct or specific instrumentation please give us a call. Until next month…Tyson Grubb | |

Instrument Choice EXPERIMENT Build your own solar cookerAustralia receives more solar radiation per square meter than any other continent. This means that we have a high potential for using solar energy as a source of renewable energy. One such way to do this is use solar panels which convert solar energy into electrical energy; another way is to use the solar energy directly is a solar cooker. Solar cookers are cheap, and can be readily made from common household items. In this month’s experiment we are going to determine if it is possible to boil an egg using only the power of the sun. Equipment used:

| |

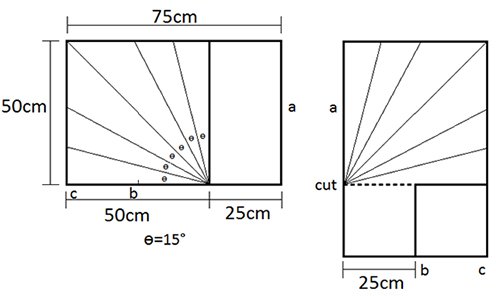

Method Cardboard from a large cardboard box was measured and cut into two 75 x 50 cm rectangles. Folds were made as per the diagram and a 25 cm long cut was made into the second sheet.   Clag glue was then used to glue the aluminium foil, shiny side up, across both pieces. This was then left to dry for 30 minutes. Once the sections were dry, section ‘a’ was stuck together using packing tape and then point ‘b’ and ‘c’ were aligned and stuck together. The solar cooker is now essentially complete.  Next, a saucepan was half-filled with water and the egg was placed in the water. A thermocouple probe was also placed in the water and then the lid to the saucepan was put in place. To help hold in the heat, even in windy conditions, an oven bag was used to cover the saucepan. The oven was then placed outside, facing toward the sun, and the saucepan was placed in the back corner. A small thermocouple probe was then placed nearby in the shade to measure air temperature. Both the air probe and the water probe were then plugged into the Testo 175 T3 so we could measure air temperature and the water temperature and the logger was started. The solar cooker was then left to heat up. | |

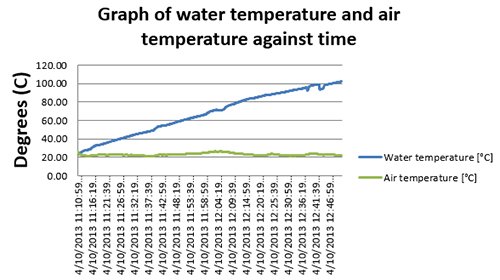

Results The air temperature remained relatively stable over the test period and remained between 22 and 25°C. The water temperature started at 23.00°C and steadily climbed over 97 minutes to reach 100°C which is hot enough to boil an egg. The display on the Testo 175 T3 was used to determine that the water temperature had reached boiling point. Data from the Testo 175 T3 was downloaded and you can view the water heating up in the following graph.   We wanted to determine whether the temperature generated by the solar cooker would be sufficient to boil an egg, and the results show that you can definitely boil an egg using only a solar cooker. | |

Food temperature and food safety.Have you ever been woken up suffering violent stomach cramps, diarrhoea or vomiting? In a lot of instances these symptoms can be put down to a case of food poisoning. This can be caused when food is poorly prepared, stored, handled or transported. The food has the potential to become contaminated with bacteria that when consumed is transferred to your stomach and cause the unpleasant symptoms detailed above. Within Australia a Food Standards Code is in place to help prevent these events from occurring within food premises. They detail requirements that all food premises must fulfil. Measuring temperature throughout food manufacturing, storage and transport forms a major component of the Food Safety Practices and General requirements standard and the instruments that can be used to assist you in measuring these. There are a number of sections of the Standard that deal with temperature measurement. The section that deals with the most basic requirement states “A food business must, at food premises where potentially hazardous food is handled, have a temperature measuring device that is readily accessible; and can accurately measure the temperature of potentially hazardous food to ±1°C.” To meet these requirements a stem thermometer that features a ±1°C accuracy is ideal. Our Scientists recommend the Dig-Stem-1 or 0560-1113 as these units are small and portable, easy to use, waterproof and cost effective. Other sections of the Standard relate to temperature control and this is prevalent to a number of processes within food premises. Temperature control as per the code Thank you from everyone at Instrument Choice - stay tuned for next months issue. Contact us. Our experts are happy to help and discuss your project. Call 1300 737 871 or write an email to [email protected] Like us on facebook. means “Maintaining food at a temperature of 5°C, or below if this is necessary to minimise the growth of infectious or toxigenic microorganisms; or 60°C or above; or another temperature if the food business demonstrates the temperature will not adversely affect the microbiological safety of the food.” Temperature control applies to receiving, processing, storing, and displaying food. There are some additional stipulations for these processes that branch off the above requirement and these can be viewed here under the various sections. The most effective way of taking these measurements is by way of an IR (Infrared) thermometer as these are non-contact and quick as they take an instantaneous reading of the surface temperature. It will allow you to point the thermometer at your food whether it is being displayed in a bain-marie, storing it in your cool room or receiving it from a supplier to establish whether or not it is within these confines. For these measurements we recommend the Dual-IR or 0560-8311 which are both robust IR thermometers that have been sold extensively for this purpose. If you wish to probe into the food rather than doing surface measurements to ensure the temperature is consistent throughout your food stuffs the Dig-Stem-1 or 0560-1113 detailed above are suitable options. If you want a thermometer that offers both forms of measurement we recommend the HACCP Food Grade TCT303F as it features a fold out probe and an inbuilt IR thermometer making it a versatile solution for any food premise. Whether you are new to a food premise or a seasoned veteran and need any assistance with selecting a thermometer for your food premise to fulfil the requirements of the standard please feel free to contact one of our friendly Scientists on 1300 737 871 for assistance. |